The estimated number of flights per day in the world is 176,000. Each of these flights involves a huge amount of technology to operate and maintain its highest operating status to move millions of passengers flying to various destinations around the world.

According to the recent NASA Ames Research Center paper, “the occurrence of defects in an aircraft could affect not only the ‘health’ of that particular aircraft but also the surrounding airspace in certain cases.

The Aircraft Health Management (AHM) market is projected to increase from USD 6.3 billion in 2023 to USD 8.6 Billion by 2028, with a projected CAGR of 6.5 percent between 2023 and 2028, according to Markets and Markets Studies estimate.

What is AHMS/ ACMS (Aircraft Health/ Control Monitoring System)?

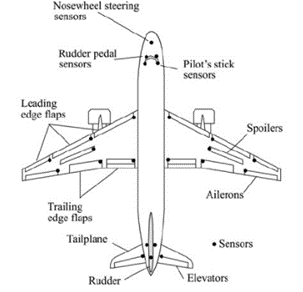

Aircraft Health Monitoring Systems (AHMS) uses real-time data from multiple sensors that are integrated into aircraft components/parts to increase aircraft safety and reliability. AHMS consists of hardware and software instruments, solutions, and techniques that conduct remote surveillance of aircraft to learn their present or potential serviceability.

Aircraft health control services are a crucial component of aircraft operations (AHMS). These systems make use of sensor-captured data in real-time and transfer data to the ground station team via Wi-Fi, GSM, or SatCom to improve reliability and safety and cope with potential concerns as soon as possible.

These systems greatly decrease inspection time as they replace visual checks, X-rays, and traditional control methods with AHMS system procedures. AHMS is combined with machine learning, IoT-enabled sensor technologies, and other sophisticated data processing systems.

The aircraft health monitoring system consists primarily of two components: The Airborne health monitoring subsystem (AHMS), the Ground Health Diagnostics Subsystem (GHMS).

Various factors increase the need for aircraft industry health surveillance systems. Some of them are-

- Increased need to enhance the aircraft’s safety, efficiency, and operational effectiveness.

- Increased demand for a system for real-time aircraft data monitoring

- Another significant factor contributing to the growth of demand for aircraft health monitoring systems is the increased adoption of connected aircraft solutions.

- The need to decrease MRO (Maintenance, Repair, and Overhaul) costs is another aspect impacting the implementation of sophisticated aircraft health management systems.

- Efficient decision making due to real-time information.

What AHMS/ ACMS Monitors?

Use of Aircraft Health/ Condition Monitoring System

- Monitoring of gas turbine engines, including cool engine fan trim balance (CFTB)

- Analysis of vibration of the airframe structure

- Analysis of Gearbox and bearing

- Monitoring of an auxiliary power unit

- Improvement of combustion in gas turbines

- Combustion chamber roar monitoring

- System use, health monitoring, diagnostic features, and engine parameters tracking in the case of incidents.

- Monitoring of oil spoilage, etc.

Let’s look at how the Aircraft Health Monitoring System is transforming aviation by anticipating future problems.

- Constant Monitoring: The Aircraft Health Monitoring System (AHMS) collects real-time data from a variety of onboard sensors and systems. It thoroughly evaluates components such as engine performance, structural integrity, avionics operation, and other factors, offering an overall picture of the aircraft’s health both in flight and on the ground.

- Predictive analytics: AHMS examines the acquired data using predictive analytics, applying algorithms and machine learning models to discover trends and irregularities. It identifies faults before they worsen by evaluating past information and real-time inputs, enabling proactive maintenance actions.

- Preventive Maintenance and Early Identification: The basis of AHMS is early detection. The system warns maintenance staff or flight crews about problems or wear-and-tear by detecting tiny deviations from typical operating parameters, allowing prompt remedial operations to avert unexpected failures.

- Data-Informed Decision-Making: AHMS provides actionable insights to aircraft operators and maintenance workers based on data analysis. This helps them to make informed decisions regarding maintenance plans, part replacements, and essential repairs, which improves aircraft health and reduces downtime.

- Increased safety and Dependability: The use of an Aircraft health monitoring system significantly enhances aircraft safety and reliability. It decreases the chance of in-flight mishaps or unplanned repairs by proactively identifying and addressing any problems, delivering a greater degree of safety for passengers and crew.

- The Development of AHMS Technology: The Aircraft Health Monitoring System is evolving with technology. Sensor technologies, artificial intelligence, and networking developments will dramatically boost the system’s capabilities, enabling more precise predictive analysis and more preventive actions.

Key Technology:

The aircraft’s health monitoring system is extremely complex, which incorporates various core technologies, e.g., fault diagnostics system, artificial intelligence, wireless sensor network, high-speed communication, etc.

The following are the few technologies involved in the aircraft health/condition monitoring system which helps in transmitting data to the ground station on aircraft failure or malfunction in real-time.

1. Fault Diagnostics System

Fault diagnostics system consists of a database, an information base, a man-machine, an inference machine, etc. The database stores the configuration parameters and the condition parameter of the aircraft with health monitoring systems.

2. Artificial Intelligence

Artificial Intelligence will interpret and coordinate data from sensors and submit data in a report that can be interpreted. In real-time, Artificial Intelligence detects and updates on possible faults and arranges correct repair timelines. Artificial intelligence technology is used specifically to validate the system’s malfunction deduction process.

3. Wireless sensor network

The nodes of these sensors combine the transducer, data processing unit, and a communication module connected via a wireless channel, creating an organized network framework. The sensor node monitors the hot, ultraviolet sonar, radar, and trembling signal of the local atmosphere with the assistance of various informative sensors.

Aircraft malfunction often has certain causes, such as abruptness, haphazardness, indecision, etc.

How eInfochips can help

eInfochips is a product engineering company with over 25 years of expertise in Device Engineering, Digital Engineering, Quality Engineering, and Silicon Engineering. With in-depth aerospace knowledge and end-to-end technical expertise and processes (DO-254, DO-178B, DO-178C, DO-160, and ARP-4754) knowledge, eInfochips has designed and developed an Android-based Engine Health Monitoring system for one of the industry leader.

DO-254 FPGA verification and DO-178C device verification have been supported for next-generation communication and navigation systems by eInfochips. We also provide hardware, software, systems, and mechanical engineering services for Avionics .

Contact our experts to find out more about how eInfochips will help the aerospace industry.