The responsibility of conserving the world that we live in has pushed us to find alternative sustainable solutions that will not harm the environment. Electric vehicles are one such solution that operates without producing any emissions. In 1832, Robert Anderson developed what we know as the first crude version of the electric car. However, it was during the 1870s, that this innovation came into practical use.

Electric vehicles run on rechargeable battery packs that are made of multiple cell modules arranged in a series and parallel. These battery packs produce several hundred volts of electricity. Various functions inside the car are dependent on them. That is why it becomes a critical component of the vehicle that requires constant monitoring and control.

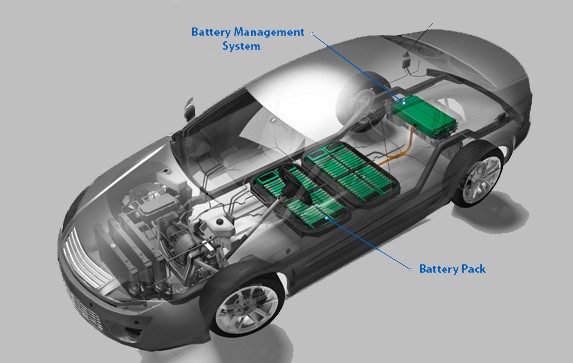

This requires Battery Management System (BMS), an embedded system, which monitors the components closer to the battery cell, as each cell needs to be closely monitored so that there are no voltage fluctuations or imbalance in voltage conditions. The BMS consists of different components that ensure that the battery runs efficiently without chances of possible failures.

What is the need for BMS?

The main function of BMS is to ensure that the battery is protected and any operation out of its safety limit is prevented. It monitors the battery pack’s state of charge (SOC) along with the state of health. BMS also manages the battery optimization via cell balancing that improves the life of the battery in the long run. The BMS will also monitor voltage, different temperature parameters, and coolant flow.

Battery Management System (BMS) for Electric Vehicles, Image Source- Circuit Digest

Lithium-ion batteries that possess high charge density, power most electric cars. These battery packs even though are not very big; can be highly unstable. Therefore, these batteries should never be overcharged or be allowed to reach a state of deep discharge at any point. Thermal Runaway is a condition where the current flowing through the battery on charging or overcharging causes the cell temperature to rise. Conditions like these can harm the lifespan or the capacity of the battery. To ensure this does not happen, we require BMS to monitor its voltage and current.

This process is very challenging as many cells are put together to form a battery pack in an electric vehicle and every cell needs to be individually monitored for its safety and efficient operation, which requires a specially dedicated system called the Battery Management System (BMS).

How Does it Aid Battery Charging?

Various factors must be taken into consideration while designing a BMS as a lot of its functionalities depend on the end application it would be used for. Let us take a look at some of these functionalities in a little more detail.

- As seen earlier, the main function of the BMS is to ensure that the battery operates within the safety parameters. Since a battery pack is made up of cells with a voltage rating of 3V, the BMS will have to ensure that the cells in the pack are not discharged beyond the 3V mark.

- Charging control is another area that requires BMS monitoring. The charging is done in two stages. The first stage is Constant Current (CC) where the charger gives constant current to charge the battery. The second stage called the Constant Voltage (CV) comes into play where a constant voltage is supplied to the battery at a very low current. The BMS ensures that these functions operate seamlessly.

- All vehicles have a fuel indicator, in the same way, EVs also have a battery state of charge (SOC) indicator. BMS helps in indicating and showing the driver the actual state of charge in the battery. The voltage and current are measurements are made using various algorithms that calculate the SOC of the battery pack. One of the methods used is called Coulomb Counting, which measures the discharging of the battery and integrates the discharging current over time to estimate SOC.

- Apart from the state of current, BMS is also responsible to monitor the state of health (SOH). The capacity of the battery may recede over time. The BMS helps in determining the state of health by measuring the age and expected life cycle of the battery based on the usage. This will help in determining the mileage on each charge.

These are some of the key functions of the BMS, which ensures that the battery operates efficiently, giving proper indications from time to time to the driver regarding the state and condition of the battery. eInfochips is a product engineering and silicon engineering company with over 25 years of experience in delivering products right from ideation, concept, and prototyping. eInfochips delivers systems and sub-systems right from core automotive product engineering, AUTOSAR compliant ECU software development, HMI design & testing, to next-gen technology enablement (edge computing, cloud, AI/ML, data analytics).

Battery Management Systems (BMS) play a pivotal role in the electric vehicle (EV) industry, offering a wide array of functions and benefits to ensure the efficient and secure operation of the vehicle’s battery pack.

- BMS Monitoring : Real-time data allows industries to track and manage the performance and condition of the battery pack, ensuring optimal operation over time.

- Safety Assurance: Ensuring the safety of electric vehicles is paramount for the industry. These features are essential for safeguarding the vehicle, passengers, and surrounding infrastructure.

- Thermal Management: Industries rely on BMS to prevent overheating during charging, discharging, and extreme environmental conditions, which is critical for the battery’s longevity and safety.

- Cell Balancing: In a typical EV battery pack, multiple cells are connected in series and parallel. BMS takes charge of cell balancing, ensuring that all cells maintain the same state of charge. This optimization enhances energy storage capacity and extends the battery’s overall lifespan.

- Energy Efficiency: Electric vehicles strive for maximum energy efficiency, and BMS plays a pivotal role in achieving this goal. By preventing over-discharging and effectively managing energy distribution, BMS helps to reduce energy waste and enhance the overall efficiency of the vehicle.

- Range Estimation: BMS provides real-time data on the battery’s state of charge, which is used to estimate the vehicle’s remaining range. This information is invaluable for both drivers and industries, as it aids in trip planning and mitigates range anxiety.

- Diagnostics and Proactive Maintenance: BMS offers diagnostic capabilities that enable early detection and resolution of potential battery issues. Industries use this feature to minimize downtime and reduce maintenance costs by addressing battery problems before they escalate.

- Regulatory Compliance: Adhering to safety and performance standards is paramount for EV manufacturers. Industries employ BMS to ensure that their vehicles are fully compliant with regulatory requirements, securing regulatory approval and market access.

- User Satisfaction : . BMS contributes to this by maintaining consistent and reliable vehicle performance, directly impacting user satisfaction and bolstering brand reputation.

- Warranty Management: Electric vehicle manufacturers offer warranties on their vehicles and battery packs. BMS data empowers industries to efficiently manage warranty claims by identifying when repairs or replacements are necessary, thus reducing warranty-related costs.

- Data Analytics in BMS: Industries leverage this data to enhance future designs, advance battery technology, and optimize energy management strategies.

- Improving Charging Infrastructure: Armed with BMS data, industries can gain a better understanding of battery charging behavior and preferences in EVs. This information is invaluable in guiding the development and enhancement of charging infrastructure to meet the needs of EV owners. In summary, Battery Management Systems (BMS) are indispensable in the electric vehicle industry. BMS technology continues to evolve to meet the industry’s ever-changing needs, ensuring the reliability, safety, and performance of electric vehicles as they become increasingly integral in the transportation sector.

CTO’s Handbook On Modern EV Charging Revolution and Technologies

To know more about our automotive expertise, contact us.