With the emergence of digital technologies and complex technology integration in the new-age medical devices, MedTech companies today need engineering partners that can undertake end-to-end product design, development, and manufacturing tasks along with IoT, cloud enablement, and managed services. Many companies working in this domain either provide software, IT, or consulting services.

MedTech firms must explore specialized partners for complex product engineering needs. There are different types of medical design partner categories such as:

- Individual consultants

- Consulting groups

- Design and development companies

- Contract manufacturers and,

- Integrated design to manufacturing partners

Let us look at a few key considerations that the companies need to look for while choosing the medical device development partner.

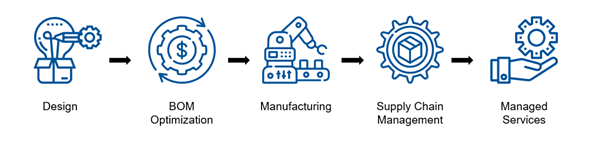

Turnkey concept-to-prototype and production-to-managed services capabilities

Medical device companies recognize that selecting the right design partner for medical product development helps them convert their ideas faster into working prototypes and finished products, saving cost and time. Independent design consultants and consultant groups are very good at rapid prototyping and proof of concepts. However, they may not be equipped with technical resources in all functional areas and may be unable to fulfill the need of the scaled production with the required compliance.

On the other hand, design and development companies may be the right choice for developing complex products as they have in-depth knowledge, streamlined processes, and an experienced team to execute the requirements. Since they don’t have large manufacturing capabilities or in-house setup, there is no proper post-development feedback available. Some firms may lack Design For Manufacturing (DFM) and Design For Testing (DFT), due to which they may need substantial re-design and development for the product. Similarly, Contract Manufacturers (CMs) are a good fit for high-volume product manufacturing with a sophisticated supply chain.

Integrated design to manufacturing companies act as single partners from the requirements to rapid prototyping to the mass production needs. These partners have in-depth expertise and experience in developing medical products and a strong understanding of the processes and industry regulations. They also have a well-defined internal Quality Management System (QMS) and documentation team. By delegating work to an integrated partner, MedTech firms can avoid the time-consuming process of resolving disagreements among multiple partners. There are various post-development issues, bug fixes, version management, variant management, and release management with L2, L3 sustenance, and support that an integrated design partner takes care of.

Certification and medical device regulatory compliance understanding

Certification and compliance are necessary for medical device commercialization without which you cannot launch the product in the market. Following FDA CFR 820.30 compliant design control process is mandatory for approval of FDA Class I, II, or III devices. IEC 62304 standard compliant-based software development is required, along with the necessary documents to submit the end-to-end software architecture, software design, development, and testing plans.

Creating and maintaining proper documentation is key in ISO 13485 compliant medical device development. These documents include various design stages documents such as design and development plan, risk management plan, design history file, usability engineering document, testing, and V&V checklists to name a few. It is a must for the medical device partners to understand the design controls, risk management, and project-specific design verification and validation strategies.

Hands-on end-to-end disruptive product development experience

To successfully convert an idea into a working prototype, companies must be cautious about the risks associated with it. If you engage with a team that lacks the necessary technical expertise in end-to-end development, the risk is higher, the learning period is longer, and ultimately, it escalates the development cost and time. Additionally, the current challenging times have led to an increase in the need for remote patient monitoring, remote diagnostics, telehealth, and connected wearable solutions. Any new medical device introduced in the market now should be equipped with IoT connectivity features. Companies can also opt for partners who have capabilities in developing connected technologies to derive valuable insights and also smoothly transmit data.

Act as an extended product engineering arm with efficient team utilization

This is also a very important factor while engaging with the external product engineering services partner. Many early-stage companies struggle with experienced resources in each stage of product development. With current market situations, many companies are facing issues in hiring and retaining full-time experienced resources, leading to delayed product launches. Experienced product development partner works as an extended arm of the client and allocates subject matter experts as and when required during the project development lifecycle. They can quickly ramp up and ramp down the required engineering resources in the project and help customers in reducing the product development cost by converting fixed costs into variable costs.

Concluding thoughts

It takes substantial time for companies to choose the right partner based on specific needs. The right approach is to be clear about the end goal – whether it is a rapid prototype, volume production, or sustainable engineering. We, at eInfochips, work with global healthcare companies and niche medical devices startups and are the preferred design partners for the design and development of their disruptive products. With our matured internal QMS system and in-depth understanding of medical device development processes, we have successfully delivered 25+ product designs to our customers. We are an ISO 13485 certified design house and engage with customers at any stage of the product development lifecycle – be it design thinking or ideation, prototyping, or production stage. Our strong value engineering experience helps our customers in optimizing their existing product BOM costs, enhancing products features, enabling connectivity, and digital transformation in existing products.

Contact our medical domain subject matter experts now for more details.